The Sliding quality test

A new concept

In 2018 Terno Scorrevoli has developed the new revolutionary Fluid System.

With this considerable system the concept of sliding system has been redefined, achieving the best sliding quality currently possible and reducing remarkably the noise during the sliding motion, thanks to the extremely light opening and closing movements.

“A new performing system is suitable to all brackets produced by our Company”.

The real revolution is a real test

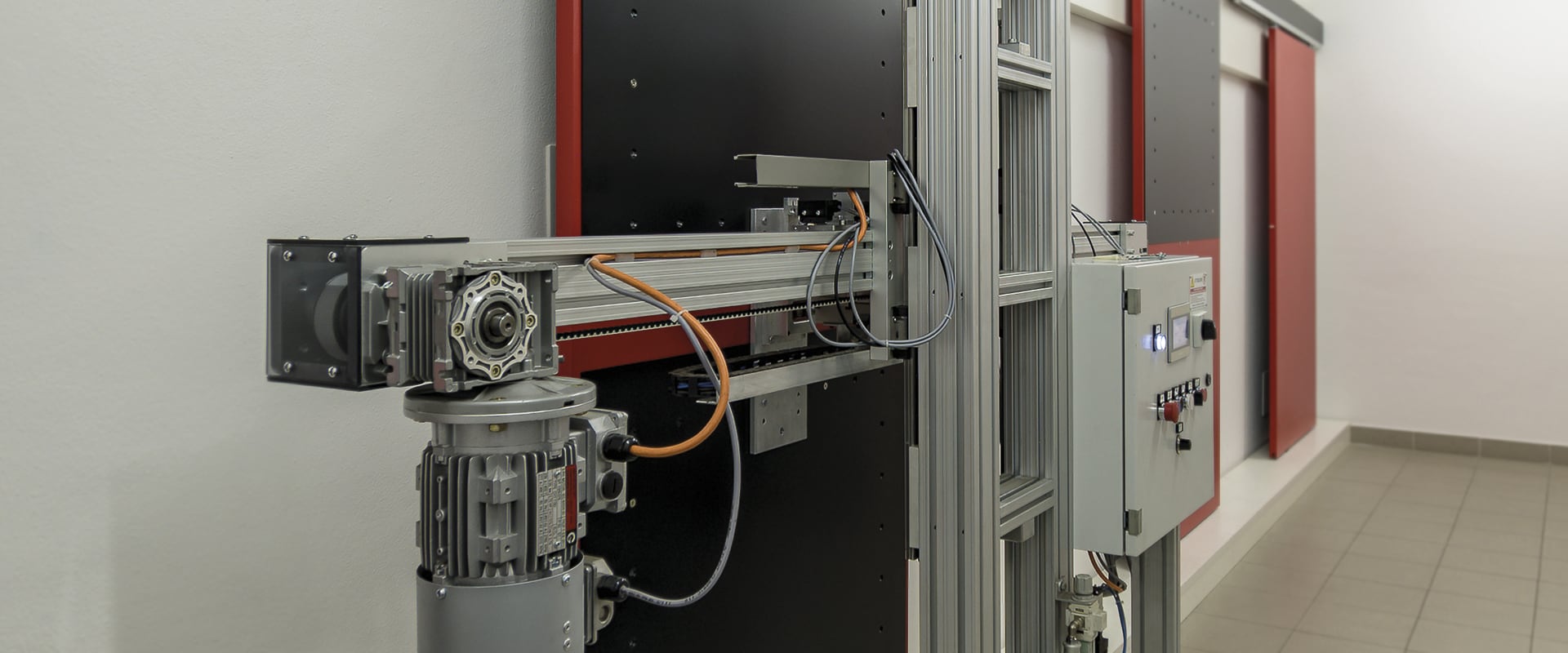

The real revolution lies in change, that’s why Terno Scorrevoli developed the “Sliding Quality Test”: a test procedure based on a machine internally engineered, with the aim of improving the performance of sliding systems and granting to the customers the best possible result.

T•LAB: how it works

The technology developed by Terno Scorrevoli allows to measure the behavior of the door during the opening and closing phases, by recording position and speed of the door/leaf along the entire test performed.

In TLAB it has been developed a testing machine with the aim of monitoring the performance of sliding systems over time.

This machine can perform tests set at different speeds.

and the testing machine developed by Terno Scorrevoli