Previous product

We will answer you as soon as possible.

Terno Scorrevoli staff

Diva Fluid Frame is suitable for solid brick wall, hollow brick wall and concrete wall.

Diva Fluid Frame is also suitable for plasterboard walls, as long as the specific anchors for plasterboard are used and the installation is done accurately.

Patented sliding doors system with aluminum frame

ITALIAN STYLE AND TECHNOLOGY

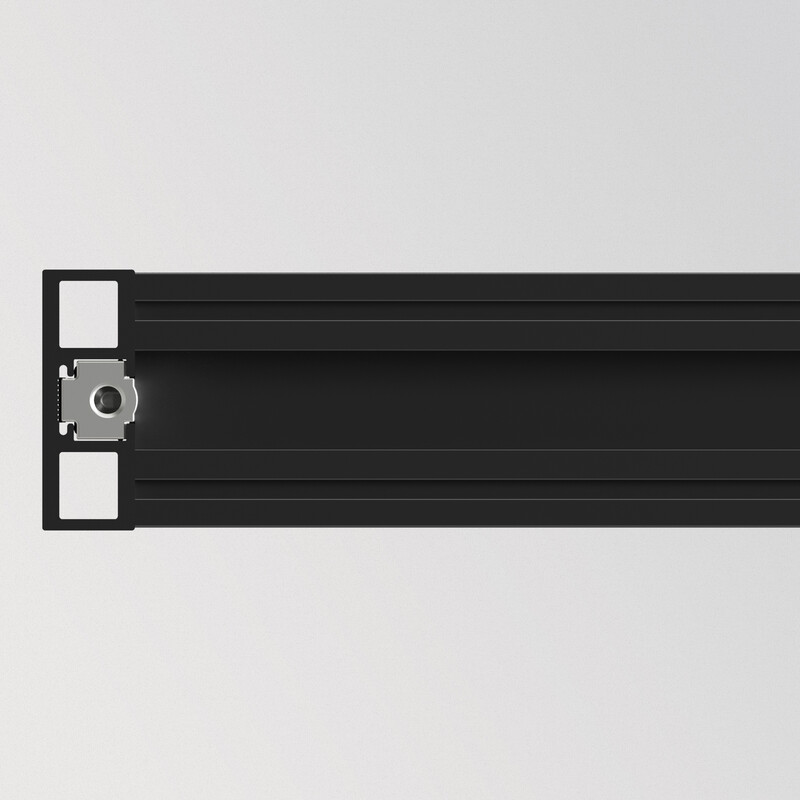

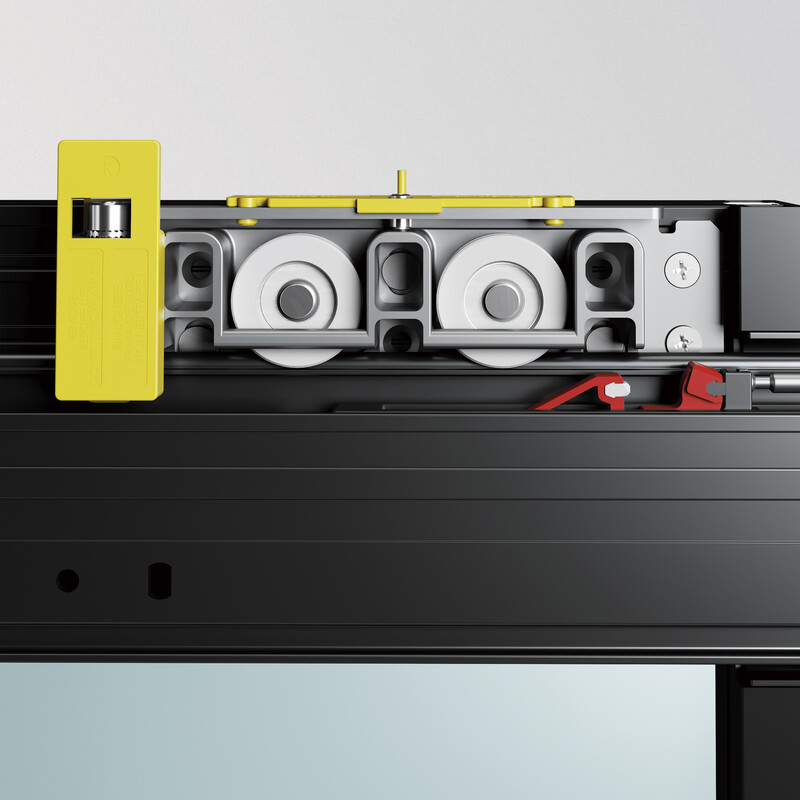

Diva Fluid is the patented sliding system specifically crafted for design barn doors, featuring exposed aluminum tracks and Fluid’s next-generation soft-closing technology. The system boasts a minimalistic style with optimized sliding trolleys recessed into the door, while patented Fluid soft-closing dampers are discreetly concealed within the track, elevating the overall door design.

Universal is the innovative aluminum door frame that, with its clean lines, reduced bulk, and high resistance, provides exceptional versatility for architects and designers.

Tubular extruded profiles

Versatility and resistance

The vertically slim uprights with reduced dimensions will minimize the visibility of extruded profiles, resulting in clean and linear lines according to latest design trends.

No additional drilling or milling processes are required.

Tubular extruded profiles, metal joints, maximal grip, load-bearing connectors, and bi-extruded gaskets – all components collaborate to ensure the glass weight is supported by vertical uprights and horizontal crosstracks, effectively reducing the pressure by half.

DESIGN & STYLE SOLUTION

The exposed aluminum sliding track set and frame’s profiles are available in various finishes, aligning with the latest design trends.

Embrace the essence of Italian design within your sliding barn doors!

INNOVATIVE & PATENTED system

Diva Fluid Frame system integrates the latest generation of soft closing dampers, equipped with our innovative Fluid technology with double springs, for smooth braking that ensures an optimal user experience.

A new patented system from Terno Scorrevoli’s years of experience.

T-LAB is the location where tests are conducted to improve performances of Terno systems and the testing machine developed by Terno Scorrevoli

In the Diva Fluid Frame system, the sliding mechanism is located at the upper part of the door. Since the door’s weight is supported from above by the wall-mounted sliding tracks, and there are no sliding elements at the bottom, Diva Fluid Frame can be effectively used on uneven floors or carpeting.

Safe and practical Anti-Unhooking System

Safety first

The new patented anti-unhooking system allows to grant the maximal safety to all installers and end-users, avoiding the door to fall in any circumstance.

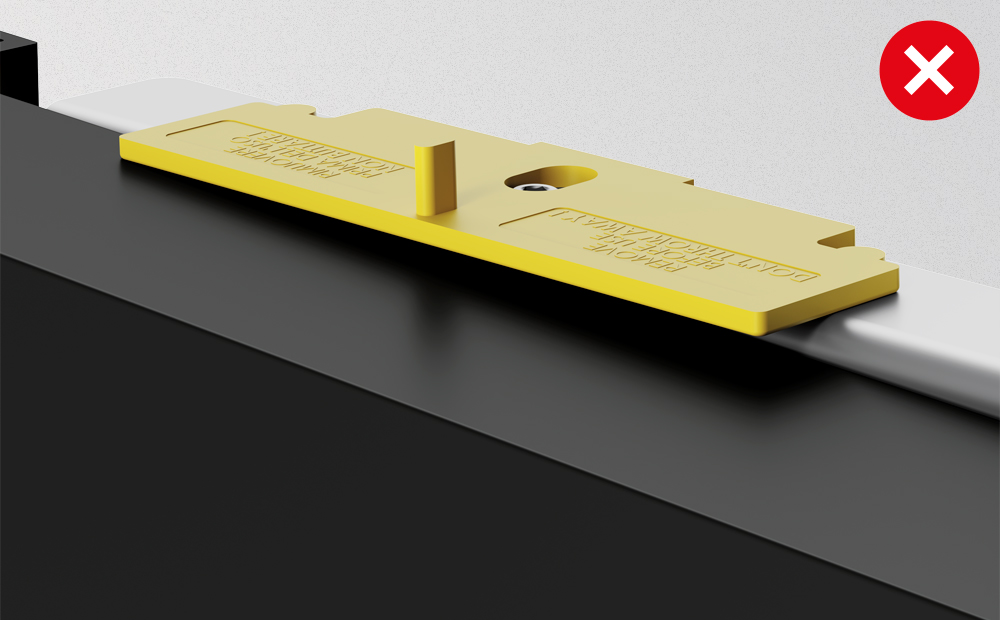

EASY TO INSTALL

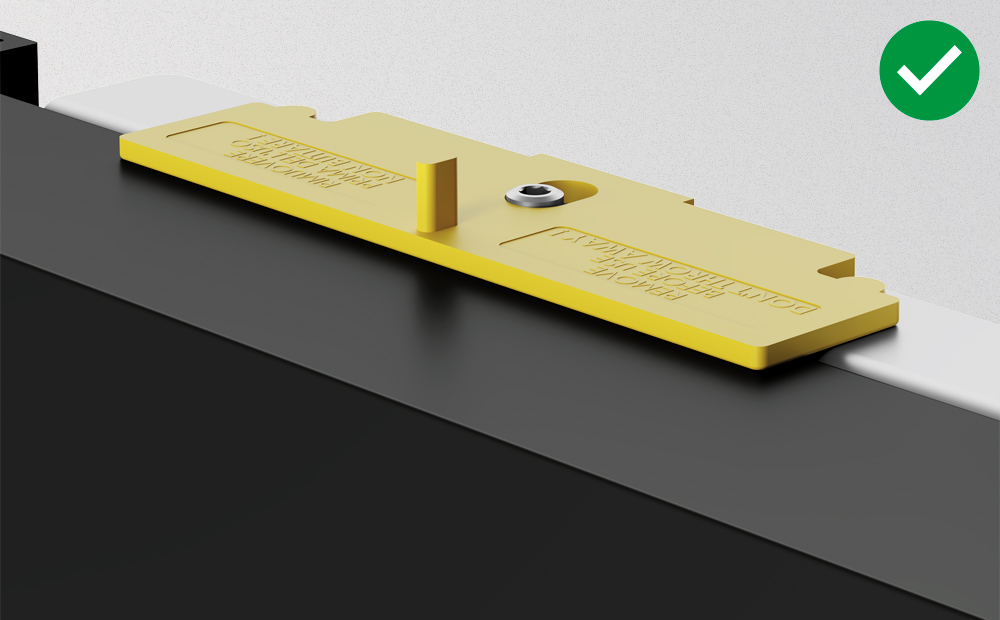

Diva Fluid Frame streamlines installation with an innovative support jig, guiding installers step by step for an intuitive and efficient assembly process.

This tool not only ensures smooth installation but also enhances overall system functionality, maximizing performance.

Diva Fluid Frame embodies the unique minimalistic style synonymous with ‘Made in Italy,’ elevating the original door design to the next level.

Reduced door opening force requirement combined with a quiet movement and an effortless soft-closing motion to ensure the best user experience possible.

The frame’s extruded profiles are tubular and connected by metal joint connectors — in order to grant maximum resistance.

No wheels at the bottom, the sliding system is at the top of the door. Diva Fluid Frame is the ideal solution for carpeted floors.

Assembling process has been simplified thanks to new support jig.

Safety is a top priority with Diva Fluid Frame system, integrating a secure and practical anti-unhooking feature to prevent any potential mistake during the installation and guarantee maximal safety for all users.

Diva Fluid Frame — datasheet

Width: 600 ÷ 1500 mm

Weight: Max 80 kg

Fluid dampers

Available finishes colours